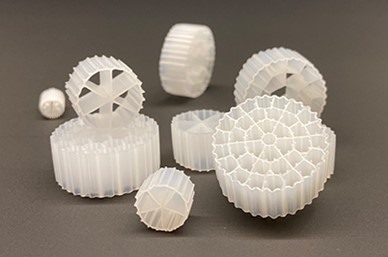

MBBR Bio Filter Media Manufacturer

Strong Moving Bed Biofilm Reactor MBBR Media

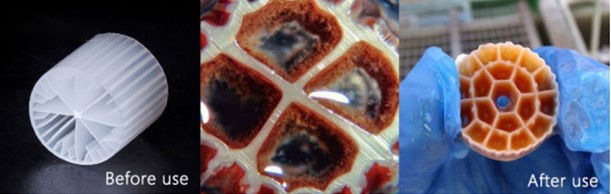

Bio filter media, used in Integrated Fixed-lm Activated Sludge (IFAS) and moving bed biofilm reaction (MBBR) system. The wastewater goes through suspending media of MBBR reactor, forming biological membrane on the surface of media gradually. With the action of microbial on the biological membrane, wastewater is purified. MBBR media can move freely in the reactor with the mixing of the water. For the aerobic reactor, the aeration will make the media move; for the anaerobic reactor, mechanic mixing will make the media move. Our MBBR media is new-developed media, has better treatment effect compared with traditional media and also long service life-100% virgin HDPE material.

Product Features

- Use virgin HDPE (no recycle) as the raw material with additive of special formula including UV and hydrophilic genes, FDA food grade. Geometric configuration based on hydrodynamics to strengthen the surface adhesive ability. it is polymer material, having high shock resistance.

- High-speed production lines. Large specific surface area, many adhesive biologia. It not only provides the room for heterotrophic bacteria growing but also create the condition for autotrophic bacteria growing. Meanwhile, it is beneficial for the biologia to denitrification and dephosphorization.

- Save energy consumption. The suitable specific weight makes the filler in suspended fluidization state, reducing the eneray consumption and increasing the shock and cutting of bubbles. In the same condition, the aeration amount can be lowered by above 10%.

Typical Applications

1.Aquaculture

2.Artificial Wetland

3.Artificial Wetland

4.Industrial Waste/ Sewage (BOD Reduction, Nitrification, Total Nitrogen Removal)

Packing 0.1cbm/bag

Technical Parameters

Model | PE05 | PE12 | |

Dimentions | mm | φ25*10 | φ25*12 |

Hole Numbers | nos. | 19 | 19 |

Protected surface area | m2/m3 | >500 | >500 |

Density | g/cm3 | 0.96-0.98 | 1.02-1.05 |

Packing numbers | pcs/m3 | >97000 | >97000 |

Porosity | % | >90 | >90 |

Dosing ratio | % | 15-65 | 15-65 |

Membrane-forming time | days | 3–15 | 3–15 |

Nitrification efficiency | gNH4-N/m3.d | 400-1200 | 400-1200 |

BOD5 oxidation efficiency | gBOD5/m3.d | 2000-10000 | 2000-10000 |

COD oxidation efficiency | gCOD/m3.d | 2000-15000 | 2000-15000 |

Applicable temperature | ℃ | 5-60 | 5-60 |

Lifespan | year | >15 | >15 |

Contact Us and see our social media like Facebook and YouTube for more information about this ETP plant.